Max carbide produce tungsten carbide waterjet nozzles with long life span.

High Quality Water Spray Parts Carbide Waterjet Nozzles for Flow Type

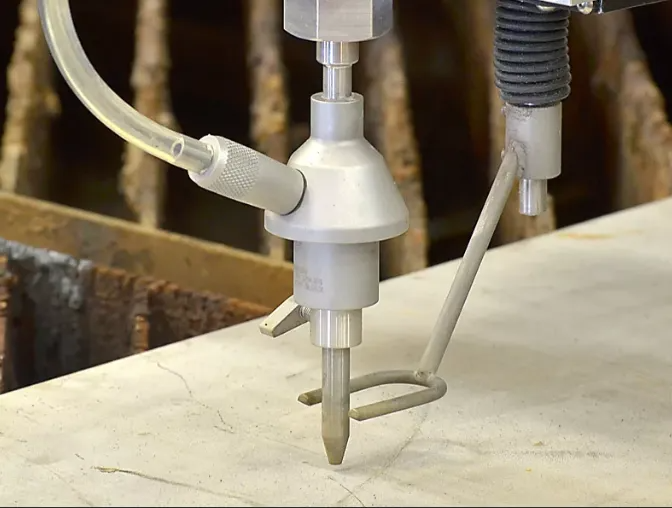

Tungsten carbide nozzle waterjet, focusing tube, water spray nozzles, abrasive watertjet nozzles use an ultra high power water jet with an added abrasive agent to cut materials with pinpoint accuracy.

Our tungsten carbide waterjet nozzles, focusing tubes are for Kmt/ Flow/ Accustream/ Omax/ Dardi cutting head.

(1) Unique advantage of tungsten carbide waterjet nozzle

1. Adopt supermicron grain size, which can result in better wear-reseistance and longer life span.

2. Content of cobalt: below 0.6%.

3. Super oxygen-resistant

4. Using HIP sintering which can increase the performance of carbide greatly.

5. Precision Ground and polished

(2)Physic character of tungsten carbide waterjet nozzle

1. Long life span: 80 hrs for finish grinding, 140hrs for rough grinding

2. Density:15.45g/cm3 —15.60 g/cm3

3. Hardness:2000Mpa-2400Mpa

4. the tolerance of polish and ground can be +0.005/-0.005m

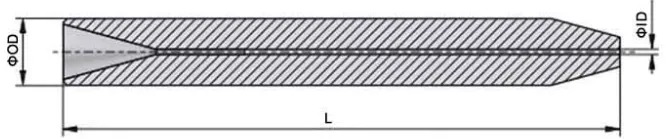

(3) Sizes of tungsten carbide waterjet nozzle

| φOD | φID | L | |||

| mm | inch | mm | inch | mm | inch |

| 6.35 | 0.25 | 0.76 | 0.03 | 76.2 | 3 |

| 6.35 | 0.25 | 1.02 | 0.04 | 76.2 | 3 |

| 6.35 | 0.25 | 1.14 | 0.045 | 76.2 | 3 |

| 6.35 | 0.25 | 1.27 | 0.05 | 76.2 | 3 |

| 6.35 | 0.25 | 1.02 | 0.04 | 101.6 | 4 |

| 6.35 | 0.25 | 1.27 | 0.05 | 101.6 | 4 |

| 7.14 | 0.281 | 0.76 | 0.03 | 76.2 | 3 |

| 7.14 | 0.281 | 1.02 | 0.04 | 76.2 | 3 |

| 7.14 | 0.281 | 0.76 | 0.03 | 101.6 | 4 |

| 7.14 | 0.281 | 1.02 | 0.04 | 101.6 | 4 |

| 7.62 | 3.000 | 0.76 | 0.03 | 76.2 | 3 |

| 7.62 | 3.000 | 1.02 | 0.04 | 76.2 | 3 |

| 8.00 | 0.315 | 0.76 | 0.03 | 101.6 | 4 |

| 8.00 | 0.315 | 1.02 | 0.04 | 101.6 | 4 |

| 9.53 | 0.375 | 0.76 | 0.03 | 76.2 | 3 |

| 9.53 | 0.375 | 1.02 | 0.04 | 76.2 | 3 |

| 9.53 | 0.375 | 0.76 | 0.03 | 101.6 | 4 |

| 9.53 | 0.375 | 1.02 | 0.04 | 101.6 | 4 |

(4) Application of tungsten carbide waterjet nozzle:

Tungsten carbide waterjet nozzles widely used in the following fields:

1. Application in metallic material cutting

To cut the metallic materials used for architectural decoration, such as stainless steel.

To make and cut the crust of machine equipment to cut all kinds of metallic spare parts.

2. Application in glass cutting

To cut glass for household electrical appliances, bathroom and architectural decoration, craftwork and automobile.

3. Application in processing tiles, stones and other building materials

To cut tiles, stones.

4. Application in composites, bulletproof material, soft material, pharmaceutical and others. With robot arm to cut automotive interior components. To cut foam, sponge, paper, rubber, pharmaceutical, nylon, carpet, etc.

Contact: Ms. Carol

Phone: +86-731-28632688

E-mail: sales@dlcarbide.com

Add: Jinshan Road(Jinshan Technology Industrial Park), Hetang District, Zhuzhou City, Hunan Province, China